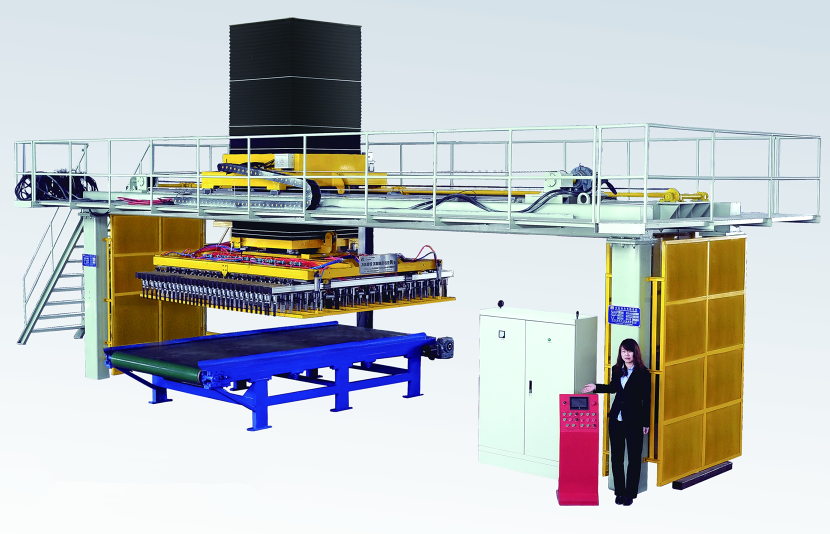

Fast speed, high output, no need to split machine, directly in the codeBillet splitting at the top of the clamping plate of the billet machine - more efficient

Hydraulic lifting, gear wheel steering, heavier load, higher stability, no shaking; The lifting system adopts the well-known brand oil pump from Taiwan, and the control valve class adopts the imported brand from Germany - with higher stability.

Lifting, marshalling, walking motor and drive are all made of French Schneider servo motor - more accurate and efficient.

Aluminum guide rail, aluminum splint seat, 65# manganese and aluminum splint, light and durable, track expansion application of Taiwan on silver brand slider bearing, walking process more stable, longer life - higher durability.

The middle pull plate is made of 45# steel plate, which is added by the equipment for accurate positioning, wear-resistant and durable.

All cylinders and pneumatic components are made of Taiwan Yadeke brand, and air pipes are made of Japanese three points brand.

Clamp type high-efficiency packaging machine

GZMP New Multi functional Code Blank System

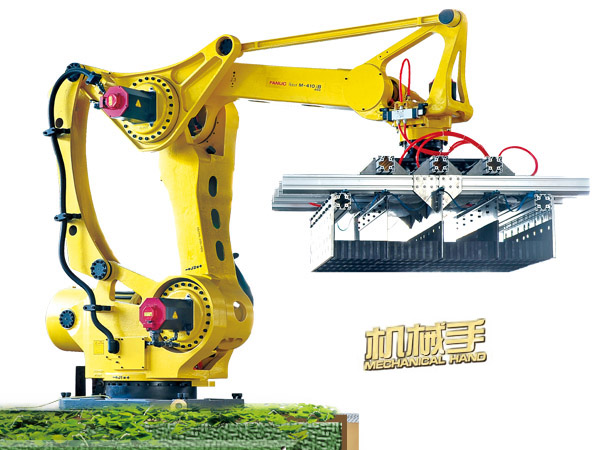

Robot coding system

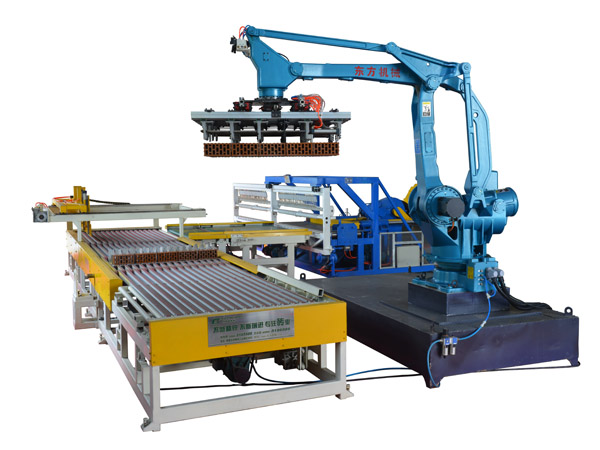

Machine coding machine

Robot coding machine

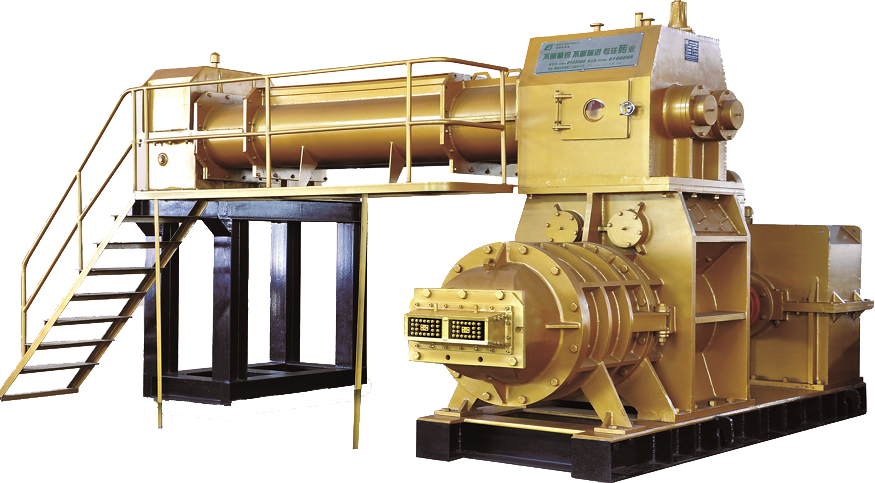

JKY60-60 two-stage vacuum extruder

Annual output of 100 million new wall hollow brick production line

Somalia

Bengal

Cameroon

Kyrgyzstan

Ethiopia

Fujian New Oriental Machinery Company is a research and development, production, sales and service in one of the science and technology enterprises, product equipment brand, quality, price has been in the tile industry for many years to maintain the advantage of the market share, in 2018 won the "national high-tech enterprise" "Fujian small giant leading enterprise" is one of China's new wall material automatic production line industry leading enterprises. After 30 years of unremitting efforts, the company has won many honors: National high-tech Enterprise, China Top 500 Building Materials Enterprise, Fujian Provincial Science and Technology small Giant leading enterprise........

New Oriental Machinery core technology and international advanced technology synchronous development, independent research and development of JKY90/85 combined six mud strip vacuum extruder equipment to fill the gap in China's mud strip. Large-section high-speed pneumatic multi-functional billet machine, servo automatic control system efficient and stable, robot billet machine, automatic billet system, the new generation of JKY70/65 large vacuum extruder and other equipment mature and stable technology, suitable for 4.6 meters to 9.6 meters section tunnel kiln, annual output of 50 million 200 million (marking bricks) new wall material automatic production line equipment, Has been widely used in the world.

◎ Provide free preliminary design scheme, overall plan, raw material testing, sintering test, to ensure that raw materials meet the requirements of brick technical consultants on-site guidance of plant construction technical problems. ◎ Technicians guide installation and debugging on site, plan reasonable equipment infrastructure, correct placement of equipment, site positioning and installation, help prepare equipment maintenance and regular maintenance, and solve customers' worries. ◎ Fujian New Oriental Machinery Company pays attention to absorbing new industry information. To promote the application of new technology. In the application of new materials and new processes, users can share scientific and technological achievements and market resources.

Fujian New Oriental Machinery independently developed large section high-speed pneumatic multi-functional coding machine, servo automatic control system is efficient and stable, robot coding machine, automatic coding system, a new generation of JKY70/65 large vacuum extruder and other equipment technology is mature and stable.

Fujian New Oriental Machinery independently developed large section high-speed pneumatic multi-functional coding machine, servo automatic control system is efficient and stable, robot coding machine, automatic coding system, a new generation of JKY70/65 large vacuum extruder and other equipment technology is mature and stable.

The distribution cabinet is an essential control system for the non burning brick machine. Whether it is loading, laying, discharging, or stacking, it is controlled by the distribution cabinet. As an important component of the electronic control system, the distribution cabinet contains a large number of electronic components, and the operation is also complex and diverse.

For most users, the maintenance and upkeep of the cement hollow brick machine in the later stage is very troublesome and cumbersome. However, we still need to do this work because only by doing a good job in the maintenance and upkeep of the cement hollow brick machine can we ensure the quality and performance of the equipment. One of its important components, the bearing, needs to be dismantled a

The long-term production of hollow brick machines often results in various defects in the extrusion forming part, which can cause various reasons for production obstacles and directly affect the production quality and equipment life of hollow brick machines.

The cleaning work of brick machine equipment needs to start from the following four aspects. Firstly, it is necessary to regularly check the operation of the equipment for any problems or malfunctions. Staff should promptly inspect the equipment for any waste and handle it promptly; We need to pay attention to sufficient materials in the equipment. We should always pay attention to whether there i

Vacuum extruder is one of the commonly used equipment in the plastic processing industry, and it usually needs to work for a long time. Therefore, how to ensure the continuous and normal use of the vacuum extruder?

How can we apply these energy-saving and environmental protection technologies from brick machine equipment manufacturers to hydraulic brick machines? 1. Dust collectors are generally used in dryers, but after our improvement, we have applied them to hydraulic brick machines, and the effect is still good, which can effectively reduce the dust and smoke generated during the production process.

Sales Department: 0594-8185588

After sales department: 0594-8186888